Metallurgy and mining industry

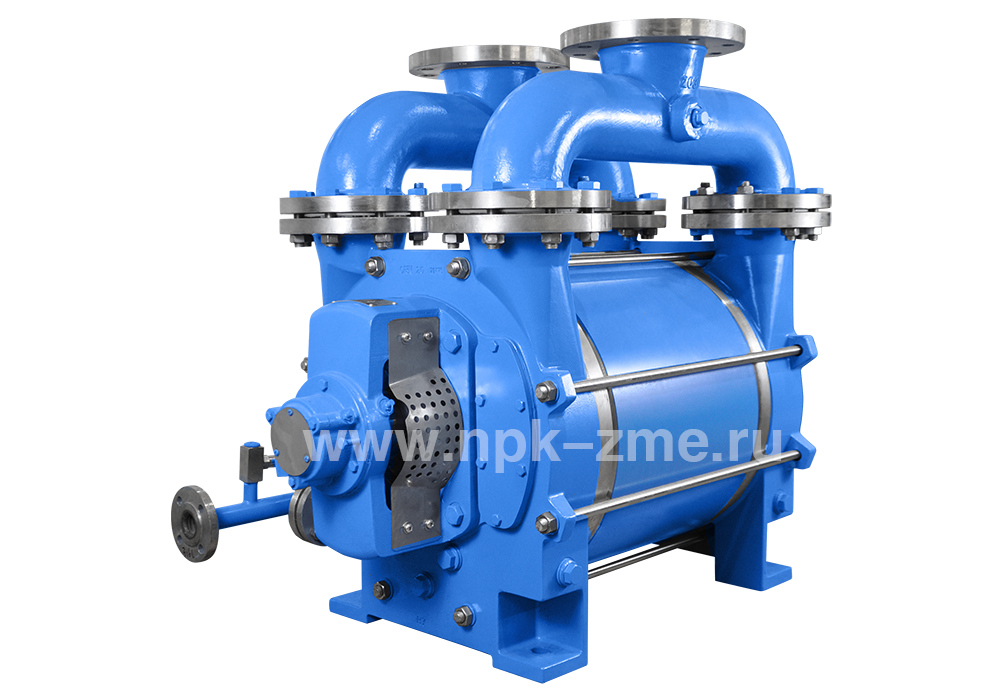

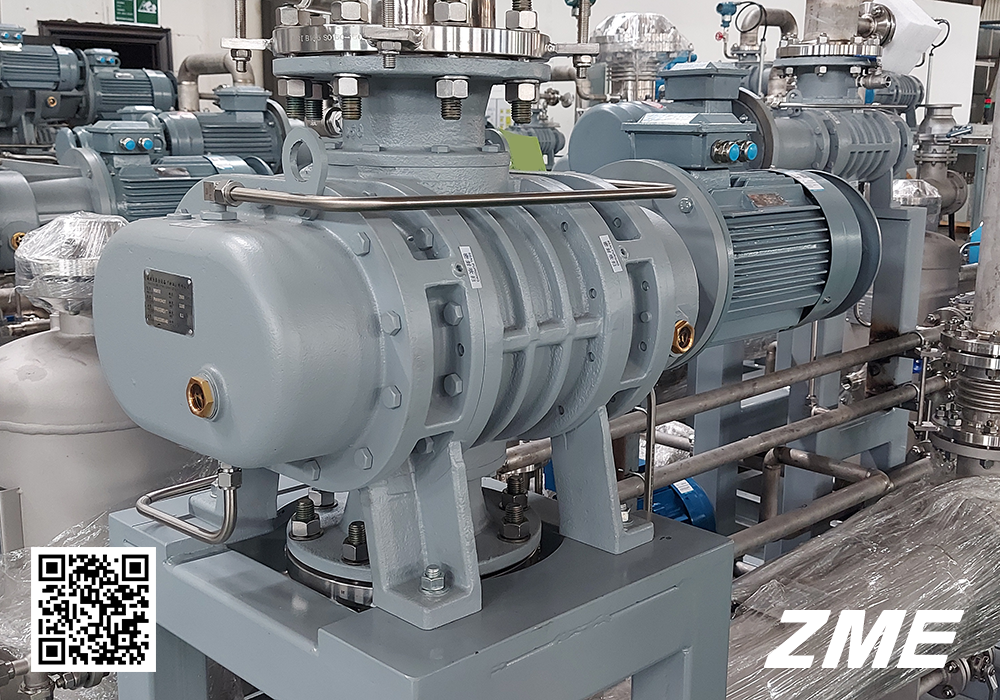

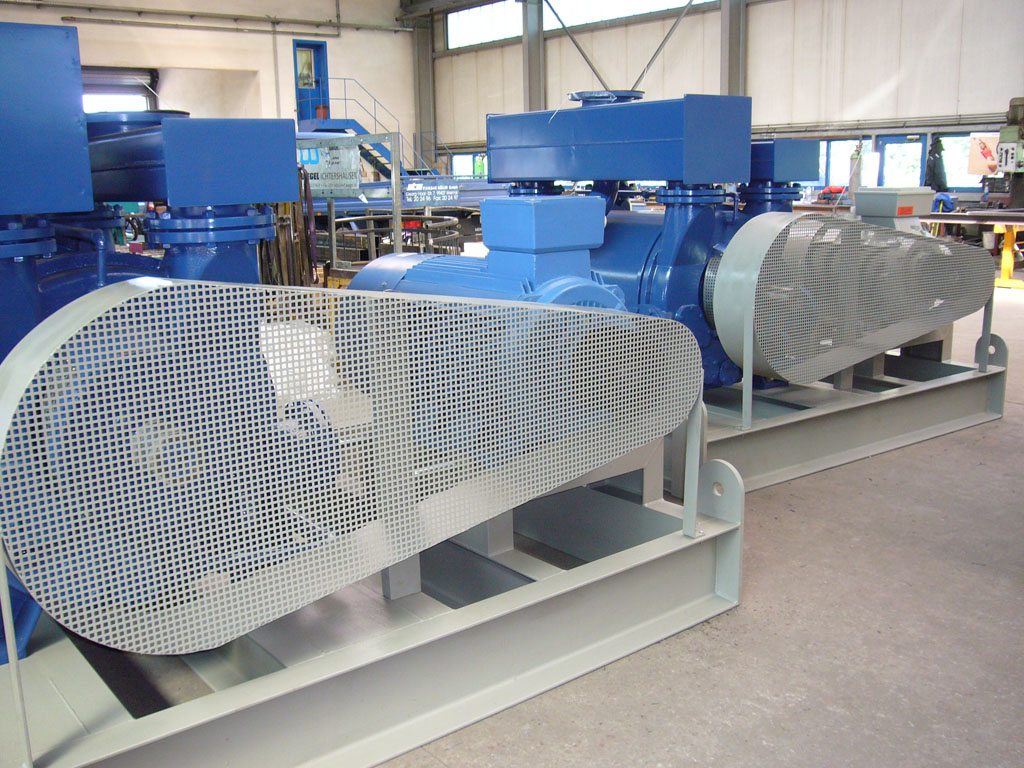

Recommended equipment

Standard units

Automated systems based on one or more rotary vane vacuum pumps, receiver and automation cabinet.

They are widely used in medical centers and in industries where it is important to maintain a set vacuum value with varying productivity.

- CVU 100-20 SL

- CVU 100-40 SL

- CVU 100-63 SL

- CVU 300-40 SL

- CVU 300-63 SL

- CVU 300-100 SL

- CVU 500-200 SL

- CVU 500-300 SL

- CVU 300-20 DL

- CVU 300-40 DL

- CVU 500-40 DL

- CVU 500-63 DL

- CVU 500-100 DL

- CVU 900-100 DL

- CVU 900-200 DL

- CVU 900-300 DL

- CVU 300-20 TL

- CVU 500-20 TL

- CVU 500-40 TL

- CVU 500-63 TL

- CVU 900-63 TL

- CVU 900-100 TL

- CVU 900-200 TL

- CVU 900-300 TL

- CVU 500-71 Q

- CVU 900-71 Q

- CVU 900-101 Q

- CVU 900-201 Q

- CVU 1600-201 Q

- CVU 900-301 Q

- CVU 1600-301 Q

Show